National Safety Month 2024: Top Tips for Risk Management

June 13th 2024

Safety Services Company

- Best Practices

- Safety Culture

In June, as we celebrate National Safety Month 2024, it’s imperative to acknowledge the strides made in safety technology within industries like construction, oil, and gas. However, despite the many advancements, challenges persist in ensuring the safety of our workforce.

Recent statistics reveal a sobering reality: one in five construction workers experiences a fatal injury annually. Furthermore, the construction industry has the highest reported rates of avoidable injuries and fatalities.

For contractors, maintaining a safe work environment isn’t just a moral obligation; it’s a fundamental business necessity. Accidents and injuries not only disrupt productivity but also escalate costs and potentially lead to legal repercussions.

It’s time to rewrite these narratives. National Safety Month provides a timely opportunity to delve into effective safety and risk management strategies.

By proactively adopting control measures, you can cultivate a culture of safety that safeguards your workers and underpins a thriving business.

Building Robust Risk Management Processes

Before implementing specific technologies and techniques for a safer work zone, we must first set up a blueprint for a more compliant culture.

Let’s build a solid foundation for your improved safety strategy.

Hazard Identification and Risk Assessments

A comprehensive risk management plan should start with mastering hazard identification. That way, you can predict potential risks before incidents occur.

This starts with conducting regular inspections, involving workers in identifying potential risks and utilizing industry-specific resources to create a comprehensive hazard inventory.

To put this concept into practice, contractors should:

-

- Schedule inspections

- Conduct a job risk analysis

- Monitor strategies and continuously improve

- Encourage worker feedback and concerns

Making these simple but effective risk management methods a standard protocol is key to safety and compliance, but they need to be followed up with proper risk control.

Risk Prioritization and Control Measures

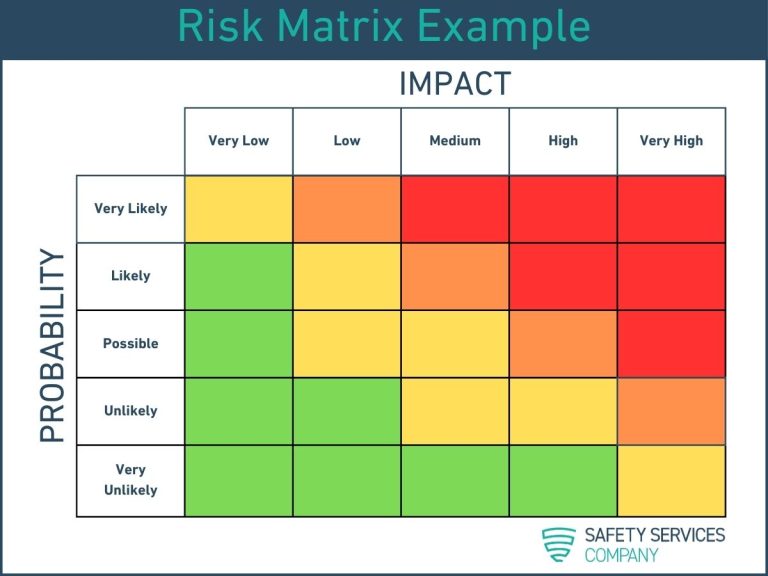

Not all hazards are created equal. Evaluate the likelihood and severity of each identified risk. This allows you to prioritize mitigation efforts and allocate resources effectively.

Here is a simple but effective risk matrix example that contractors can use during the risk mitigation phase:

For each identified hazard, be sure to develop a clear and actionable mitigation plan. Once you’ve identified and prioritized risks, it’s time to implement control measures. This might involve engineering controls like:

-

- Safety protocols

- Administrative controls

- Fall protection systems

- Personal Protective Equipment (PPE)

Risk management is an ongoing process. Regularly monitor risks and the effectiveness of your control measures, investigate near misses and incidents, and adapt your strategies as needed.

Leveraging Technology for Enhanced Safety Measures

With a strong framework, we can then leverage other safety measures, like new innovative technologies. Developments in safety tech offer a wealth of tools to bolster your risk management efforts.

Some of the latest technological advancements include:

-

- Digital Hazard Identification and Management Software: These types of software solutions simplify the process of identifying, documenting, and tracking hazards on your sites. In some cases, such as Digital Twin Technology, you’re able to simulate safety hazards and test measures before real-world implementation. They can also facilitate communication and reporting of safety concerns.

- Virtual Reality (VR) Safety Training: VR training allows workers to experience simulated job site scenarios in a safe environment. This immersive training can significantly improve workers’ understanding of safety protocols and hazard recognition.

- Wearable Technology: Advancements in wearable technology offer a range of safety applications. For example, wearable sensors can monitor worker fatigue, posture, and exposure to environmental hazards.

- Drone Inspections: Drones can conduct safe and efficient inspections of hard-to-reach areas or high-risk environments, minimizing worker exposure to potential hazards. According to a Construction Technology Report in 2021, at least 37% of construction companies were using drones on job sites at that time.

Each of these tools has made job sites safer by providing training and performing risky tasks that were previously only done by humans.

Cultivating a Culture of Safety For Your Team Beyond National Safety Month

Did you know that OSHA recently called for the industry to build safety into the work culture to prevent some of the most prominent causes of injuries and fatalities on job sites?

While framework and technology play a crucial role in risk reduction, creating a culture of safety requires a multi-pronged approach.

A Commitment to Leadership

Visible leadership commitment to workplace safety sets the tone for the entire organization. Leaders must actively promote safety practices, allocate resources, and hold everyone accountable for safety protocols.

Good leaders also foster open communication and employee engagement. Workers are more likely to embrace safety when they feel empowered and involved in the process.

Encourage feedback about safety concerns, include workers in developing safety protocols, and recognize and reward safe work practices.

Ensure clear and consistent communication about safety protocols, hazard identification, and incident reporting procedures. Regularly conduct safety meetings and training sessions to keep every team member informed and engaged.

Then, make all these efforts more effective by noting every incident, near miss, and learning opportunities. Investigate incidents thoroughly, identify root causes, and implement corrective actions to prevent future occurrences.

Master Your Work Site Risk Management for National Safety Month 2024

National Safety Month is a great time to take stock and refine your risk management strategies. However, remember that safety is an ongoing commitment.

By integrating the strategies outlined above, contractors can foster a culture of safety that goes beyond a single month and becomes a core value of the organization.

This proactive approach leads to a safer work environment for your team, a more productive workforce, and a stronger, more resilient business.

How Can Safety Services Company Support Your Safety Efforts?

Working in our industry comes with plenty of risks. That’s why your focus must remain on safety. If you are a contractor, Contractor Management Services can help you every step of the way, ensuring that your focus remains on the field while we oversee your prequalification and compliance.