Oil and Gas Digital Twin Technology and Generative AI

May 31st 2024

- Industry News

The world’s energy demands continue to rise, particularly in the Oil and Gas industry. This creates a growing need to embrace sustainability and optimize operations with innovative technlogies.

Exploring the integration of Oil and Gas Digital Twin technology in this sector not only highlights advancements but also sets the stage for significant operational transformations.

That’s why events like the recent Oil & Gas Digital Twin Conference 2024 serve as essential platforms for industry leaders and innovators. It allows them to explore how new technologies can unlock a new era of efficiency, sustainability, and progress.

Enter Digital Twin and Generative AI technology—potential game-changers positioned to revolutionize the Oil and Gas industry. But what exactly are Generative AI and Digital Twin technology, and how can they empower contractors to achieve exceptional results?

Here we’ll dive into these innovative technologies by dissecting what they are, their benefits, and how creating a synergy between the two can enhance the future of the Oil and Gas industry.

What is Digital Twin Technology?

First, let’s answer the question: What is a Digital Twin?

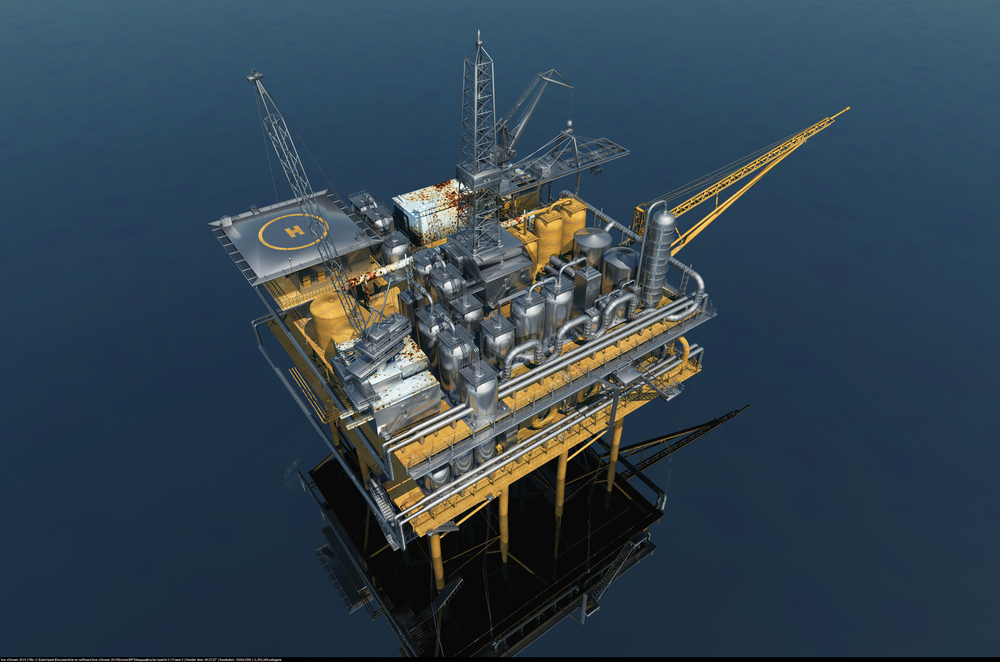

If you don’t know, a Digital Twin is a virtual representation of a physical asset—a refinery, a pipeline, or even an entire oilfield. A Digital Twin is a constantly evolving data-driven model that mirrors its real-world counterpart in real time.

Sensors embedded in physical equipment feed data into the Digital Twin, enabling continuous monitoring of performance, health, and environmental impact.

For example, imagine a virtual oil rig, constantly updated with information on pressure, temperature, and equipment wear.

This allows for proactive maintenance, identifying potential issues before they escalate into costly downtime or safety hazards.

Moreover, utilizing advanced machine learning algorithms, these digital models can continuously fine-tune their predictions, enhancing accuracy over time. This dynamic approach ensures that contractors in the Oil and Gas sectors can rely on up-to-date information to make informed decisions.

Benefits of Leveraging Oil and Gas Digital Twin Technology

Now that we know what a Digital Twin is, what are the benefits of using this technology that make it a game changer?

The adoption of Digital Twin technology in Oil and Gas enables enhanced predictive analytics and operational insights, offering a clear pathway to optimized resource utilization and reduced environmental impact.

- Predictive Analytics for Maintenance: By analyzing historical data and real-time sensor readings, Digital Twins can predict potential equipment failures. This allows for proactive maintenance.

- Process Optimization: Businesses can identify bottlenecks and optimize processes by simulating different scenarios within the Digital Twin. This leads to smoother operations, reduced waste, and increased output.

- Remote Monitoring: Digital Twins enable remote monitoring of critical assets, allowing for real-time troubleshooting and faster response times to issues.

Companies using Digital Twins and leveraging this technology will have a significant competitive advantage. This will enable more efficient operations, enhance predictive maintenance, and improve decision-making through real-time data analysis and simulation capabilities.

Embracing the Digital Revolution of Generative AI

The Oil and Gas industry is no stranger to new technology. Whether you’re a seasoned contractor or just starting, familiarizing yourself with digital twins is an investment in the future.

The industry has been adapting and evolving this technology since the turn of the century. But Generative AI brings it into the spotlight today.

Generative AI, a subfield of Artificial Intelligence, can create entirely new data. Unlike traditional AI models that analyze existing data, Generative AI (or GenAI for short) can generate realistic and new content. This includes text, code, images, and even 3D models, such as the one below.

In particular, the application of Oil and Gas Digital Twin technology and AI operations transforms how contractors manage and execute projects, offering unprecedented levels of efficiency and innovation.

The Benefits of Leveraging Generative AI in the Workforce

The benefits of GenAI and leveraging AI in the workforce are vast. Essentially, you can create a safer worksite environment by using GenAI to predict and mitigate safety hazards and incidents before they happen.

Artificial intelligence (AI) can also be leveraged to improve efficiencies and productivity. In the context of operational efficiency, Generative AI offers several advantages:

- Scenario Planning: Generative AI can create simulations of various operational scenarios, including unexpected events like equipment failures or fluctuations in demand. This allows businesses to develop contingency plans and mitigate potential risks.

- Process Improvement: By analyzing historical data and identifying patterns, GenAI can suggest innovative solutions for improving existing processes. This can lead to faster production times, higher quality outputs, and reduced costs.

- Product Development: Generative AI can be used to design and optimize new products. By simulating different product variations and their performance within a Digital Twin, businesses can identify the most efficient and effective designs.

With this in mind, how does GenAI bring Digital Twins into the Oil and Gas industry’s main discussions?

Creating a Synergy Between GenAI and Digital Twin Technology

Having Digital Twins and Generative AI work in tandem unlocks a new realm of operational efficiency.

For example, it allows for closed-loop optimization. Data from the Digital Twin feeds into the Generative AI model, which then generates recommendations for optimizing the physical system.

The Digital Twin can then be updated with these optimized settings for continuous improvement. This process not only streamlines operations but also allows for continuous fine-tuning of systems based on predictive insights generated by machine learning algorithms, further empowering contractors in Oil and Gas to enhance operational efficiencies.

Generative AI can also analyze data from the Digital Twin to predict future operational trends and potential issues. This allows businesses, such as Oil and Gas companies, to make proactive decisions and avoid disruptions, safety hazards, and unnecessary costs.

Implementing Data-Driven Insights

The combination of real-time data from the Digital Twin and the creative power of Generative AI fosters a culture of data-driven innovation.

Contractors can experiment with new concepts and solutions within the safety of the virtual world before implementing them in real-time.

Successfully leveraging Digital Twins and Generative AI requires careful planning and execution.

The key is to create a robust data infrastructure for collecting, storing, and analyzing the vast amounts of data generated by Digital Twins and AI models.

Businesses must also invest in talent with expertise in data science and engineering to bridge the gap between the physical and digital worlds.

To add, remember as with any data-driven technology, robust cybersecurity measures are crucial to protect sensitive operational data.

As the Oil and Gas industry continues to evolve, the role of digital twin technology becomes increasingly central, promising new levels of efficiency and safety previously unattainable.

A Future of Innovation for the Oil and Gas Industry

Widespread adoption of Oil and Gas Digital Twin Technology along with AI has massive potential for the future of the Oil and Gas industry.

By improving operational efficiency, optimizing resource use, and prioritizing safety, these digital innovations can lead to a more safe, sustainable, and profitable future.

Events like the “Oil & Gas Digital Twins Conference 2024” are vital platforms for industry leaders to share their knowledge and accelerate growth.

Partner with Safety Services Company for Added Efficiency

How can compliance management solutions support these types of initiatives?

You already know that staying on top of the latest innovations in Oil and Gas Digital Twin technology is vital to long-term success. With all the implementation, documentation, and optimization contractors need to focus on, don’t let managing your prequalification and hiring client requirements be an added burden.

Partner with Safety Services Company for peace of mind, and let us do the heavy lifting so you can focus on being a leader in your field!

Want to read our most recent blogs? See more below:

- TRIR Calculator: Turn Incident Data into a Safer Workplace

- RESRG Automotive Joins ISNetworld®: Advancing Contractor Readiness with ISNetworld® Compliance

- Custom Safety Solutions: Why One-Size-Fits-All Doesn’t Work in Safety

- 5 Benefits of Digital Safety Training Tools Over Traditional Options

- ATI Has Joined ISNetworld®: Your Guide to Staying Compliant

Disclaimer: This content is for informational purposes only and may not reflect current regulations, best practices, or legal requirements. While accuracy was intended when published, some laws and standards may have changed. Do not rely on it as legal or professional advice.

For guidance specific to your situation, consult a legal professional or refer to the latest regulations. If you have questions or need assistance with additional compliance matters, our team is here to help.