Walking-Working Surfaces Safety Training

Prevent Slips, Trips, & Falls with OSHA-compliant Walking-Working Surfaces Training

What Is a Walking-Working Surface?

A walking-working surface is pretty much what it sounds like: Any place employees walk to get to or from a working from which they perform work. To be more accurate, it can be any surface: horizontal or vertical area and you don’t necessarily need to walk on or through it. It could be a ladder, a catwalk, a driveway, a roof, a scaffold, a stairway, or any number of other surfaces. Whatever the case, these can pose unique hazards in any industry. For example, slips, trips, and falls from walking-working surfaces are still the most common workplace injury. That’s why it’s extremely important to train employees and provide them with safe work practices, preventing slips, trips, and/or falls.

Stop Slips, Trips and Falls with OSHA Walking-Working Surfaces

Some of the most hazardous working surfaces are those at a height from which a fall could be deadly. While OSHA does not maintain an independent fall protection standard for general industry, it does maintain rules for fall protection as a subsection of 29 CFR 1910 Subpart D – Walking-Working surfaces. 1910.28 states that it’s the duty of employers to provide protection to those exposed to falls and falling objects. For example, for any surface higher than 4 ft. that has unprotected sides, employees must provide one or more of the following:

- A guardrail system

- A safety net system

- A personal fall arrest system

Walking & Working Surfaces Products and Prices:

Walking-Working Surfaces Safety Training Kit

Duration: 45 minutes

Level: Intermediate

Languages: English and Spanish

Digital: $550.00

Digital and Hard Copy: $675.00

Description: DIY TRAINING KIT: COURSE A – This course is designed to provide basic knowledge and awareness around walking-working surfaces. It’s meant to give an overview for potential trainers who can then use their knowledge of specific working surfaces, fall protection systems, or engineering solutions.

Injury and Illness Prevention Plan Manual

Languages: English and Spanish

Digital Delivery: $600.00

Digital and Hard Copy: $725.00

3-Year Maintenance: $590.00

Description: MANUAL – The Injury and Illness Prevention Plan is a customized manual written to federal OSHA regulations. Pick from over 120 elective policies, such as walking-working surfaces, to build a complete safety manual. Opt into manual maintenance to ensure your manual remains up-to-date when regulations change.

Walking-Working Surfaces Training

Chapter Add-On

Languages: English and Spanish

Digital: $100.00

Digital and Hard Copy: $125.00

Description: CHAPTER ADD ON – Add the walking-working surface chapter to an existing Safety Services Company Injury and Illness Prevention Plan, if this chapter was not selected at the time of purchase.

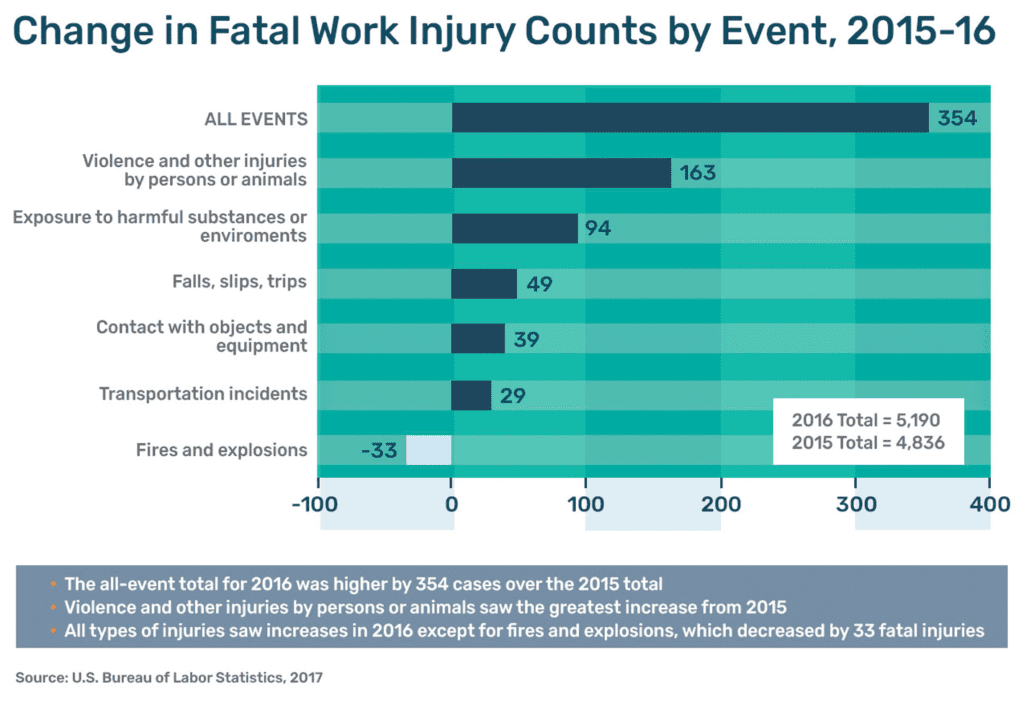

In 2016, falls to a lower level due to slips, trips and falls accounted for 849 fatalities. Of the fatality cases where the height of the fall was known (591 cases), 47% were falls from only 15 feet.

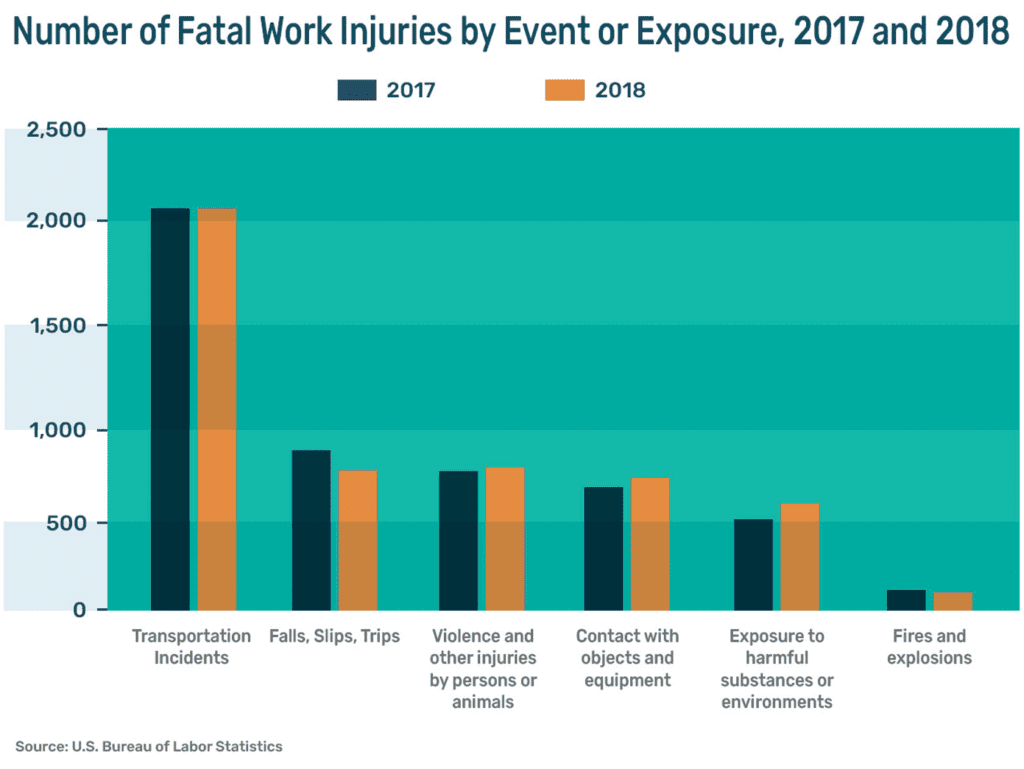

From 2017 to 2018, fatal falls, slips and trips decreased from 887 in 2017 to 791.

The decrease appears to suggest that training and awareness makes a difference. In 2017, OSHA expanded its walking-working surfaces standard. In addition to updates to the slip, trip and fall hazard rules, it introduced the requirements for personal fall arrest systems. This likely corresponds with the decrease in fatalities.

Hazards of Walking-Working Surfaces

The hazards of walking-working surfaces can include slips, trips, falls, and contact with hazardous materials. Walking-working surfaces can be especially dangerous when they are wet or icy, which can cause employees to lose their balance and fall. Additionally, many different types of materials and equipment can be found on walking-working surfaces, which can create hazards for employees.

To help prevent injuries, employers must provide their employees with proper training on how to safely work on walking-working surfaces. Employees should be taught how to identify potential hazards and how to safely avoid them. Additionally, employers should provide employees with the proper safety gear and equipment, such as slip-resistant shoes and fall protection devices.

The dangers these hazards pose can result in fatal injuries.

Good Housekeeping for Surfaces

The employer must make sure that walking working surface conditions are clean and dry when possible. Drainage or other safety systems are required for wet surfaces. Walking-working surfaces must be kept free of hazards such as sharp or protruding objects, corrosion, ice, and others. Surfaces must support the weight needed and have a safe way to come and go from the working area.

Safe walking working surfaces also need regular inspections and maintenance. Hazardous conditions must be fixed before the surface is loaded or worked on again. If this affects the structural integrity, a qualified person must supervise or perform any repairs.

Wear Fall Protection Equipment

These working surfaces include portable ladders, elevator shafts, and communication towers. (OSHA 1910.23). Uncommon ladders, such as; mobile ladder stands with special design needs, and step bolts used in manhole entries are explained in OSHA 1910.24. All OSHA walking-working surface have access needs, including ramps, stairways, ship stairs, alternating tread stairs, and standard stair design (including rise & run measurements of the steps based on the stair angle to the horizontal). These are explained in OSHA 1910.25.

Barricade Work Zone for Safety

Dockboards are also classified as walking-working surfaces. Information such as use, misuse, and intended loads are explained in OSHA 1910.26. Scaffolding and rope descent systems (RDS) (a suspension system that allows a worker to come down from a scaffold in a safe manner) are in OSHA 1910.27.

In OSHA 1910.28, just as in 1926.501, the employer not only has a duty to maintain fall protection safety standards, but unlike 1926.501, they also have a duty to provide for dropped object protections (OSHA 1910.29). This can be done by the use of catch platforms, tethers on tools, toe boards on scaffolds, and other mitigations.

Get Online Walking-Working Surfaces Training

Online Walking-Working Surfaces training provides a great introduction or deep dive into the topic of Walking-Working Surfaces. Whether employees need a refresher or initial training, this can help prevent injuries or demonstrate to OSHA that a company has taken appropriate measures. In addition to Walking-Working Surfaces training, our online platform, SafetyConnect, provides companies a central location to store all things safety-related. Store additional training, certificates, or safety policies, for example.

Do-It-Yourself Walking-Working Surfaces Training

If you have a competent and qualified Walking-Working Surfaces trainer of your own, Safety Services Company offers Walking-Working Surfaces training kits. These kits include the following:

- An interactive digital presentation

- A facilitator guide

- A student guide

- Knowledge assessments

- Certificates of completion

- An attendance sheet

The format supports training offline, at a remote job site, for example. It also allows for both classroom-style learning or individual training.

Walking-Working Surfaces Policy for Safety Manual

A complete Walking-Working Surfaces policy should be specific to your business and work sites. Safety Services Company offers manuals customized for your business.

Walking-Working Surfaces Prequalification Services

Are you working with ISNetworld (ISN), Avetta, Veriforce, or any of 30+ prequalification platforms to land a contract with a safety-minded organization? Safety Services Company offers safety prequalification services to help companies meet prequalification platform requirements for Walking-Working Surfaces and other such safety topics. These services are not limited to but include:

- A consistently maintained health, safety, and environmental manual complete with a Walking-Working Surfaces policy

- A dedicated safety and compliance manager to support your business, review your prequalification needs quarterly, and maintain your prequalification accounts

- OSHA 300 log maintenance to meet annual reporting requirements

Management of insurance documentation

Walking-Working Surfaces Toolbox Talks / Walking-Working Surfaces Safety Meetings

Safety training doesn’t make much sense if it’s not revisited or applied. To reinforce training, Safety Services Company offers Safety Meetings, or toolbox / tailgate talks, as they’re often called. These safety meetings can be delivered all at once or in weekly installments, curated based on the work that you do.

Set up your workplace properly to help prevent costly slips, trips and falls

Walking-Working Surfaces Regulations

Federal

29 CFR 1910.21 – Scope and Definitions

This OSHA standard defines scope of the walking-working surfaces subpart and defines the commonly used terms throughout the code.

29 CFR 1019.22 – General Requirements

This standard establishes the general requirements for walking-working surfaces, such as keeping the surfaces clean and orderly to prevent slipping, falling objects, or contact with hazardous materials like nails or glass.

29 CFR 1910.23 – Ladders

This standard discusses ladders in the context of walking-working surfaces and establishes the requirements for working on or around them.

29 CFR 1910.24 – Step Bolts and Manhole Steps

This standard establishes requirements for step bolts and manhole steps, which are rungs or bolts affixed to a structure. They’re meant for standing on or climbing.

29 CFR 1910.25 – Stairways

This standard lays out requirements for stairs as a walking-working surface. This includes rules such as when handrails are required.

29 CFR 1910.26 – Dockboards

This standard covers dockboards, which act as walking-working surfaces to bridge gaps between transport vehicles and a loading platform, e.g., a truck trailer and a warehouse loading dock.

29 CFR 1910.27 – Scaffolds and Rope Descent Systems

This section describes rules for scaffolds and rope descent systems used in general industry.

29 CFR 1910.28 – Duty to Have Fall Protection and Falling Object Protection

This standard establishes that it is an employer’s duty to provide fall protection and falling object protection where necessary for walking-working surfaces.

29 CFR 1910.29 – Fall Protection Systems and Falling Object Protection-Criteria and Practices

This regulation establishes the criteria and practices for the use of fall protection systems and falling object protection.

29 CFR 1910.30 – Training Requirements

29 CFR 1910.30 is about the rules for how people have to be trained to work on hazardous surfaces. These rules make sure that people are safe when they work on these surfaces.

California

8 CCR 3270 – Access – General

This section establishes the minimum safety requirements for employee access to elevated or sunken locations. This helps protect employees from falls or dangers of working in confined spaces.

8 CCR 3270.1 – Use of Rope Access Equipment

This regulation helps protect employees from the many dangers that can be found while using rope access equipment, including falls, electrocution, and getting hit by moving objects.

8 CCR 327 – Openings

This standard discusses minimum requirements for the use of openings in walking-working surfaces. It protects employees from the many dangers such as falls or contact with hazardous materials.

8 CCR 3272 – Aisles, Walkways, and Crawlways

This standard relates to aisles, walkways, and crawlways where slips, trips, and falls are common.

8 CCR 3273 – Working Area

This section of code defines minimum safety requirements for working areas such as permanent walkways, which should be kept free of obstructions or projects, kept well-maintained, and free of slip hazards like water or grease.

8 CCR 3274 – Valves and Controls

This standard covers valves and controls on walking-working surfaces. It helps protect employees from the many dangers that can be found while using valves and controls, including asphyxiation, explosions, and chemical burns.

Safety industry fact:

Over 29% of accidents reported

in the workplace consist of

slips, trips and falls

making them the most common cause of workplace injuries.

Whenever any issue needs resolved, Paula has always helped to make the situation correct with the utmost speed! I’d rate my experience at a 12 out of 10 stars!!!

RicH&Hoy