Help Avoid Citations and Fall Accidents

Fall protection is the duty of all employers who have employees that work at heights. Every year, fall protection is an OSHA top-ten, most-cited violation. With Safety Services Company’s assistance, companies can avoid citations and deaths (or injuries) by following OSHA guidance.

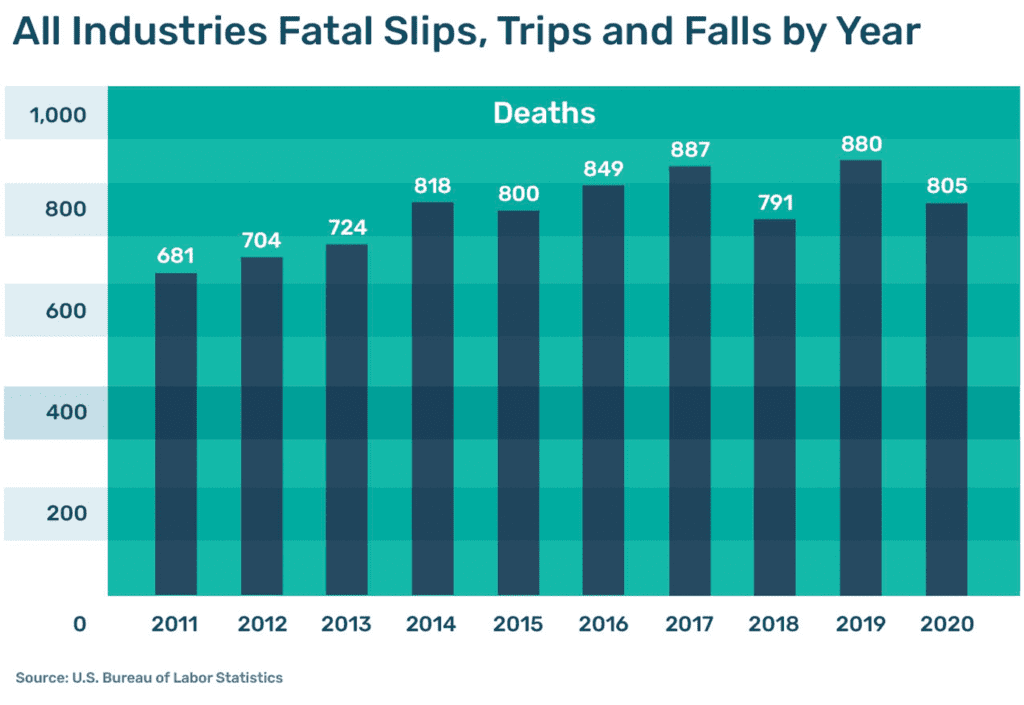

In 2020, 645 people died on the job because of a fall to a lower surface per the Bureau of Labor Statistics (BLS). Forty two percent of all construction deaths on the job are because of falls per the National Institute of Occupational Safety & Health (NIOSH).

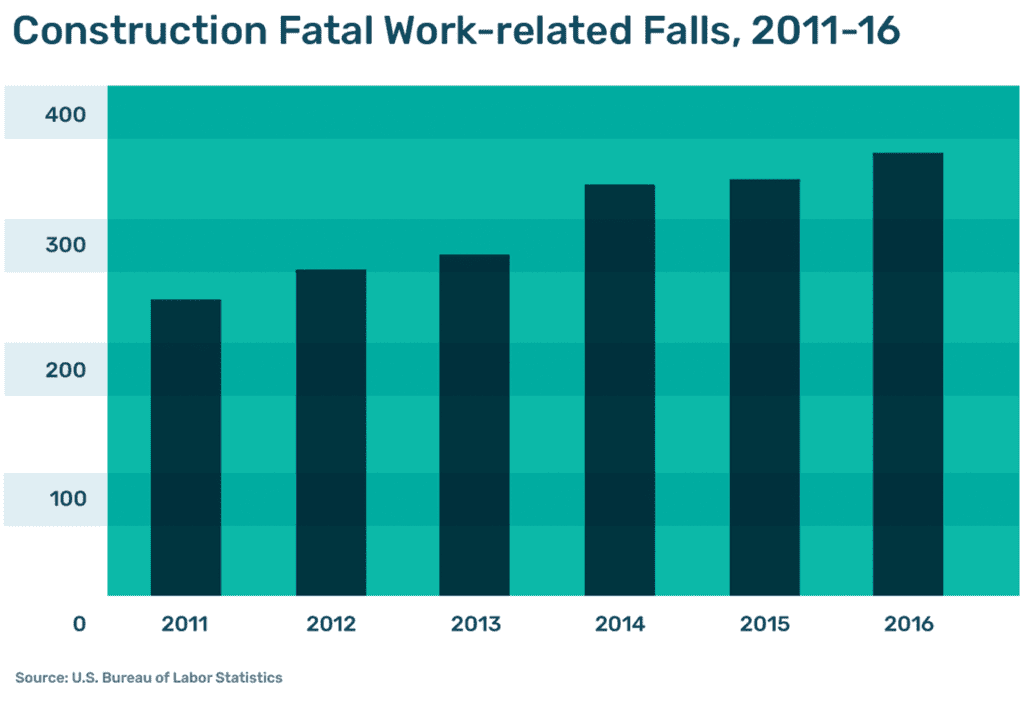

Fatal falls to a lower level have steadily increased from 2011-2016 in the construction industry.

Fall Protection Products and Prices:

Fall Protection Safety Training Kit

Duration: 45 minutes

Level: Intermediate

Languages: English and Spanish

Digital: $550.00

Digital and Hard Copy: $675.00

Description: DIY TRAINING KIT: COURSE A – This do-it-yourself training kit provides you with all the materials needed to conduct in-house, classroom-style fall protection training. Great for training the trainer. No internet connection required. Materials include: Facilitator guides, student guides, wallet cards, course completion certificates, training log, and an interactive presentation.

Injury and Illness Prevention Plan Manual

Languages: English and Spanish

Digital Delivery: $600.00

Digital and Hard Copy: $725.00

3-Year Maintenance: $590.00

Description: MANUAL – The Injury and Illness Prevention Plan is a customized manual written to federal OSHA regulations. Pick from over 120 elective policies, such as fall protection, to build a complete safety manual. Opt into manual maintenance to ensure your manual remains up-to-date when regulations change.

Fall Protection Training

Chapter Add-on

Languages: English and Spanish

Digital: $100.00

Digital and Hard Copy: $125.00

Description: CHAPTER ADD ON – Add the fall protection chapter to an existing Safety Services Company Injury and Illness Prevention Plan, if this chapter was not selected at the time of purchase.

Onsite Fall Protection Training

Onsite Training

Languages: English and Spanish

CONTACT FOR PRICING

Description: A certified safety professional will visit your work site and train up to 15 employees at a time. This will allow you to get customized training specific to the work you’re doing and the equipment you use.

Topics Covered for Fall Protection in Construction

A competent person regarding fall protection will do OSHA fall protection training (1926.503). The below list shows training topics for fall protection.

- How to identify fall hazards

- Fall protection systems

- Fall protection systems and equipment

- Inspection of fall protection systems and equipment

- Assembly, disassembly, and maintenance of fall protection systems

- Use of guardrails, personal fall arrest systems, safety net systems, warning line systems, safety monitoring systems, controlled access zones, and other protections used

- Erection of overhead protection

- Limitations of mechanical equipment during low-sloped roof work

- Handling and storage of fall protection materials/equipment

- The role of employees in fall protection plans

- Employee roles in safety monitoring systems, if these are used

- OSHA fall protection standards

- Rescue

OSHA fall protection training must be in a language covered workers understand.

Fall Protection in General Industry

In addition to Fall Protection Standards, employers must also comply with Walking-Working Surface Regulations. These regulations are found in 29 CFR Part 1910, Subpart I. They specify requirements for safe walking and working surfaces in the workplace.

Employers must ensure that all walking and working surfaces are free of hazards and safe for employees to use. They must also provide employees with proper footwear and clothing to protect them from potential hazards.

Employers must also provide adequate slip, trip, and fall protection for employees working at height or on uneven surfaces. This can be done by using guardrails, safety nets, personal fall arrest systems, or other appropriate measures.

Fall Protection Equipment Inspection

Inspections are needed for fall protection. These include inspection of fall arrest PPE such as harnesses, lanyards, carabiners, self-retracting lifelines and others done before each use and work shift. Signs that gear should be replaced include wear, red threads, mildew, sun/heat damage or defective components. Companies must freely provide usable PPE to employees.

A competent person (or competent rescuer) thoroughly inspects all equipment such as all safety harnesses and safety lanyards, as well as systems annually for damage and safety. Qualified persons inspect to verify that fall protection systems have been installed properly.

Fall Protection Site Orientation

Use OSHA fall protection plans for site orientation, as part of the OSHA fall protection training, and inspections.

If the employer cannot use standard equipment such as guardrails, safety harness, safety lanyards, safety nets, and/or other conventional systems and equipment because it presents greater hazards, an OSHA fall protection plan is needed. These jobs include leading edge work, precast concrete erection and residential construction. These are written by or with a qualified person and have information about the job site and all fall hazards. The plan includes fall protection methods and equipment to be used-having information on the processes including assembly, installation, maintenance, and disassembly procedures for the equipment as well as instruction needed for handling, storing/securing fall protection equipment.

Fall protection plans should also have a fall rescue plan. Rescue is needed to avoid suspension trauma in fall arrest situations. After the fall, hanging in the harness needs to be as short a time as possible.

Get Online Fall Protection Training

Online fall protection training provides a great introduction or a deeper understanding of fall protection. This is perfect to refresh, supplement, or reinforce internal policy or training. In addition, our online training platform, SafetyConnect is a feature-rich content and learning management system to support all of your safety needs: from storage of important fall protection safety and training records to conducting remote demonstrations of Fall Protection equipment specific to your workplace.

Do-It-Yourself Fall Protection Training

If you have a competent and qualified fall protection trainer of your own, Safety Services Company offers fall protection training kits. These kits include the following:

- An interactive digital presentation

- A facilitator guide

- A student guide

- Knowledge assessments

- Certificates of completion

- An attendance log

Fall Protection Policy for Safety Manual

A complete fall protection policy should be specific to your business and work sites. Safety Services Company offers manuals customized for your business.

Fall Protection Prequalification Services

Working with ISNetworld®, Avetta®, Veriforce®, or any of 30+ prequalification platforms to land a contract with a safety-minded organization? Safety Services Company offers safety prequalification services to help companies meet prequalification platform requirements for fall protection and other such safety topics. These services are not limited to but include:

- A consistently maintained health, safety, and environmental manual complete with a fall protection policy

- A dedicated safety and compliance manager to support your business, review your prequalification needs quarterly, and maintain your prequalification accounts

- OSHA 300 log maintenance to meet annual reporting requirements

- Management of insurance documentation

Fall Protection Toolbox Talks / Fall Protection Safety Meetings

To reinforce OSHA fall protection training, companies must regularly talk about fall protection topics. Weekly safety meetings and toolbox talks allow this. Safety Services Company offers industry-guided Fall Protection safety meetings sent in weekly or biweekly installments. Choose from over 1000 topics, including fall protection.

Guardrails, safety nets and personal fall arrest systems prevent injuries from falls

Fall Protection Regulations

Federal

29 CFR 1910.29 – Fall Protection Systems and Falling Object Protection – Criteria and Practices

This section of federal code provides the requirements for fall protection systems and falling object prevention for general industry.

29 CFR 1926.500 – Scope, Application, and Definitions

This federal standard includes scoping and definitions for fall protection in construction jobs.

29 CFR 1926.501 – Duty to Have Fall Protection

This standard establishes when employers must provide fall protection systems with regard to construction.

29 CFR 1926.502 – Fall Protection Systems Criteria and Practices

This standard lays out the criteria for required fall protection systems.

29 CFR 1926.503 – Training Requirements

This standard establishes the requirements for fall protection training, namely that those employees exposed to fall protection hazards in the workplace must receive training.

California

8 CCR 1669 – General

This section of Cal/OSHA Title 8, Subchapter 4, Article 24, Fall protection establishes that fall protection must be used when performing work from dangerously high locations (at 15 ft. or above) such as beams or trusses.

8 CCR 1670 – Personal Fall Arrest Systems, Personal Fall Restraint Systems and Positioning Devices

This section of title 8 code defines the criteria for an approved fall protection system, and further requirements for components of a fall protection system, as required by 8 CCR 1669.

8 CCR 1671 – Safety Nets

When a fall protection system is a clear no-go or workers are at 25 ft. or more, safety nets must be used. This Cal/OSHA standard writes out those rules.

8 CCR 1671.2 – Controlled Access Zones and Safety Monitoring Systems

This standard defines the rules for controlled access zones and safety monitoring systems in California.

Safety industry fact:

Fall protection is an OSHA top-ten, most-cited violation

Very pleased with Safety Services Company. The services that they provide gives our company piece-of-mind that we are meeting safety criteria set forth by the industry and individual clients.

Schelley B.