OSHA Top 10 Mini-Series: Hazard Communication

September 17th 2019

Safety Services Company

- Safety Culture

- Safety Training

OSHA Top Ten List of Cited Violations for 2018

Every year, the Occupational Safety and Health Authority publishes its list of the Top 10 Most Cited Violations according to Federal OSHA. As of September 30th 2018, the top two most frequently cited standards following OSHA worksite inspections are violations relating to the Fall Protection Standard (29 CFR 1926.501) and the Hazard Communication Standard (29 CFR.1200). In 2018, there was a whopping 7,216 citations for Fall Protection, while over 4,000 Hazard Communication citations were recorded. Both of these standards frequently fall in to the Top 10 category, and violations often result in what could be considered easily preventable injuries. We will therefore be dedicating the next two articles to focusing on firstly on the Hazard Communication standard, and secondly examining the Fall Protection standard to give our readers important insights into compliance with both regulations.Hazard Communication: What is it?

As a small business owner, you will most likely come across chemicals in the workplace, whether it be in the office or at a worksite. Chemicals may range from cleaning fluids, paints and pesticides, to more obvious hazardous chemicals such as chlorine or ethanol. Chemicals are as prevalent in the workplace as they are diverse, and with many beneficial and oftentimes innocuous applications, it is difficult to always see the adverse effects that they may cause to people. However, employers should be aware that chemicals may pose health threats as well as physical hazards in the workplace and should therefore be documented carefully to avoid injuries or environmental/property damage. Wherever workplaces use or store hazardous chemicals, they must have a written hazardous communication program in order to inform employees how the OSHA standard is applied at that facility.What is a Hazardous Chemical and Do I Have Any at My Workplace?

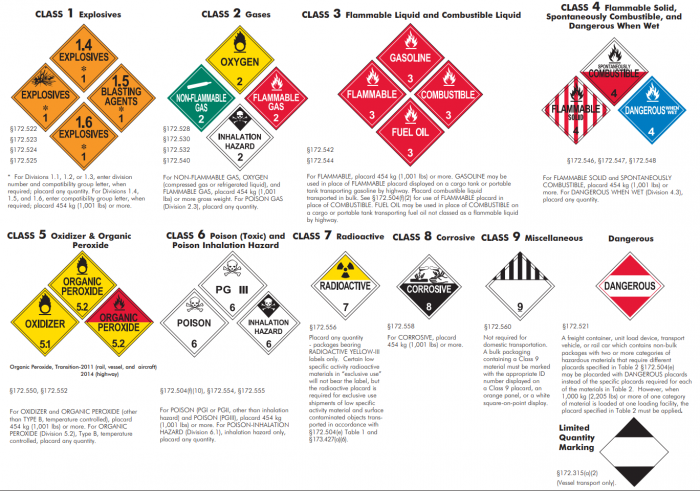

It is important to note that prior to 2012, there were two systems for classification of chemicals in the United States. As of 2012, the Hazard Communication Standard was updated so that its system of classification is aligned to the United Nations Globally Harmonized System of Classification and Labeling of Chemicals (GHS). These two systems are often referred to in Hazard Communication so it is important to be aware of both systems. Chemicals are classified as hazardous where they pose a risk as either a physical or health hazard. These risks may include for example- flammable liquids, combustible dusts, carcinogenic materials or asphyxiants. Employers who receive chemicals that are considered hazardous must also receive information about the chemical to determine the risks it may pose. This information may be provided in the form of labeling, or may also be found on the chemical Safety Data Sheets (SDS). Chemicals fall into a variety of hazard classes, and may be further subdivided in to hazard categories under the Hazard Communication Standard (see infographic below). Hazard classifications are typically completed by the manufacturer of the chemical, while the end user (you) is responsible for being aware of the hazards of a particular chemical as identified by labeling or the SDS. https://www.fmcsa.dot.gov/sites/fmcsa.dot.gov/files/docs/Hazardous_Materials_Markings_Labeling_and_Placarding_Guide.pdf

https://www.fmcsa.dot.gov/sites/fmcsa.dot.gov/files/docs/Hazardous_Materials_Markings_Labeling_and_Placarding_Guide.pdf

What Should Be Included in a Hazard Communication Program?

As highlighted above, employers who use, transport, store chemicals, or maintain any working environment where employees may be exposed to hazardous chemicals must have a written hazard communication program. Also termed ‘Right to Know’, employees have the right to be aware of any chemicals that they may be exposed to that can pose a threat to their physical safety or health. It is also beneficial for employers to maintain a hazard communication program in order to manage their workplace, substitute hazardous chemicals for less harmful ones where possible, and reduce the likelihood of worker injury resulting in increased worker’s compensation costs. Small businesses looking to create a Hazard Communication program should follow as a guide these six steps in order for it to be effective:- Obtain a copy of the OSHA Hazard Communication standard and read/understand its requirements

- Create a written Hazard Communication Plan

- Label all chemical containers

- Create a folder with the most up-to-date SDS documents for all chemicals onsite

- Train employees on chemical hazard identification

- Periodically review and update Hazard Communication Program

1. Understand CFR 29 1910.1200: Hazard Communication Standard

This standard can be accessed online and provides specific information on what should be included in the program, how containers should be labelled, information on Safety Data Sheets and also includes requirements for training. Some worksites have limited applications under the hazard communication standard so it is important for employers to clearly understand the scope of the standard and how it directly applies to their business.2. Create a Written Hazard Communication Program

Employers should create a written hazard communication program that specifies how they intend to comply with 1910.1200 by documenting their compliance with the standard. This includes how they will incorporate warnings and labels for the hazardous chemicals as well as how employees will be informed and trained on hazards and how to manage them where possible. The plan should also identify key individuals responsible for managing the program. The plan should include an inventory of all hazardous chemicals at the worksite, how the employer will inform employees about hazards including those posed by non-routine tasks, and what considerations will be taken for multiple worksites.3. Label All Chemical Containers

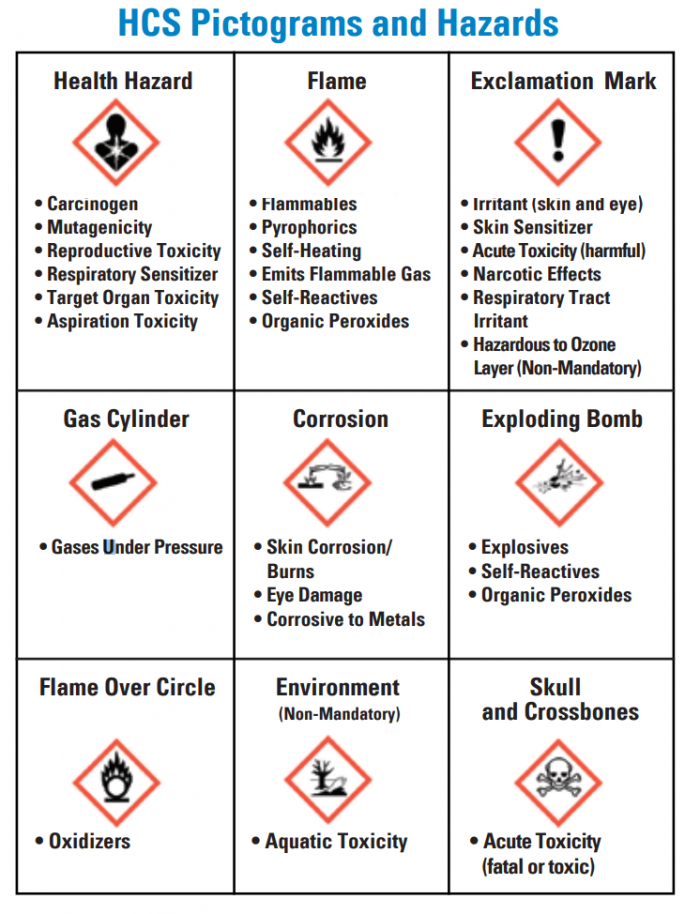

Labeling is a crucial step in any Hazard Communication Program. Labels should include a product identifier (product name), signal word (identifies the hazard severity), hazard statement, a pictogram depicting the type of hazard, and the contact information of the chemical manufacturer or responsible party. Pictograms are an easily identifiable way of displaying to an observer the hazards associated with a particular chemical. Some common symbols include: https://www.osha.gov/Publications/OSHA3491QuickCardPictogram.pdf

OSHA also provides a quick reference

guide to the Hazard Communication Standard for labels and pictograms that provides a concise

look at how this exercise should be completed for all chemicals at a workplace.

https://www.osha.gov/Publications/OSHA3491QuickCardPictogram.pdf

OSHA also provides a quick reference

guide to the Hazard Communication Standard for labels and pictograms that provides a concise

look at how this exercise should be completed for all chemicals at a workplace.

4. Create a Folder with the Most Up-to-date SDS Documents for all Onsite Chemicals

All companies should maintain a Safety Date Sheet (SDS) folder that contains the SDS documents for all chemicals onsite. This folder should have the most up-to-date SDS for a particular chemical on file and should be periodically reviewed to ensure that old SDS documents are removed and new chemicals have an SDS on file. SDS documents contain the following sections, organized in such a way that important emergency response information is provided first and technical chemical and manufacturer information is documented in later sections:- Identification

- Hazard(s) identification

- Composition/information on ingredients

- First-aid measures

- Firefighting measures

- Accidental release measures

- Handling and storage

- Exposure control/personal protection

- Physical and chemical properties

- Stability and reactivity

- Toxicological information

- Ecological information

- Disposal considerations

- Transport information

- Regulatory information

- Other information

5. Train Employees on Chemical Hazard Identification

Employees must be trained on the various hazards of chemicals onsite. Employers should therefore create a training that is effective in identifying hazardous chemicals in their workplace, the hazards associated with those chemicals, and the ways in which workers can protects themselves. Employees should also be informed of typical locations where these chemicals may be present as well as the methods of identifying a potential release of the chemicals. Training should also brief employees on the general requirements of a hazardous communication program and the forms of labeling and SDS files that are used and kept onsite.6. Periodically Review and Update Hazard Communication Program

The use of chemicals at a workplace is a dynamic operation that can change quite frequently depending on the type of operations at a particular site. Therefore, it’s critical that employers review their hazardous communication program periodically to ensure that it is up-to-date. To do this, employers must consider:- Determining if there are any changes to 1910.1200 and if any changes are required to their hazardous communication program

- Responsible persons are fulfilling their tasks under the program

- SDS inventory is up-to-date

- Training is up-to-date

- Procedures are accurate

- Labeling of all containers is accurate

- The program is effectively communication chemical hazards

Disclaimer: This content is for informational purposes only and may not reflect current regulations, best practices, or legal requirements. While accuracy was intended when published, some laws and standards may have changed. Do not rely on it as legal or professional advice.

For guidance specific to your situation, consult a legal professional or refer to the latest regulations. If you have questions or need assistance with additional compliance matters, our team is here to help. Click here to connect with our experts.

Disclaimer: This content is for informational purposes only and may not reflect current regulations, best practices, or legal requirements. While accuracy was intended when published, some laws and standards may have changed. Do not rely on it as legal or professional advice.

For guidance specific to your situation, consult a legal professional or refer to the latest regulations. If you have questions or need assistance with additional compliance matters, our team is here to help.